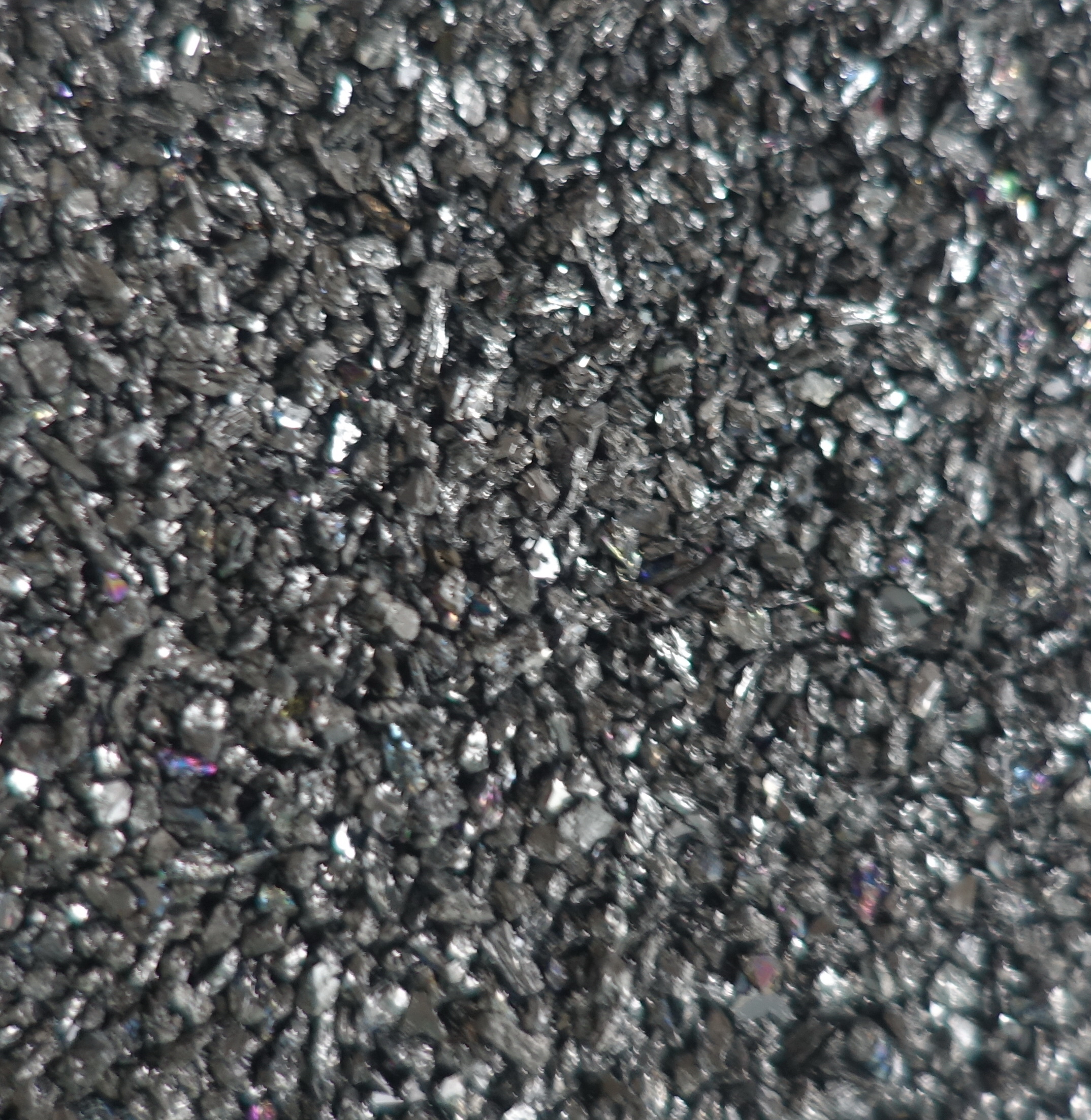

黑色碳化矽是以石英砂,石油焦為主要原料及添加劑高溫冶煉而成,呈黑色。用它製成的顆粒適用於磨料磨具製造,噴砂,拋光,加工石材,鐵,塑膠等材料及耐火材料。由於化學性能穩定,還是理想的耐酸堿腐蝕材料。

Application | Grade | Grit Size | SIC | Fe(Iron) | C(Carbon) | Magnetic admixture |

Abrasive | AG | F12-F20 | 98.0 | 0.25 | 0.25 | 0.13 |

F24-F90 | 98.0 | 0.25 | 0.25 | 0.15 | ||

F100-F120 | 98.0 | 0.25 | 0.3 | 0.15 | ||

F150-F180 | 97.0 | 0.3 | 0.3 | 0.15 | ||

F230-F280 | 97.0 | 0.3 | 0.3 | 0.15 | ||

F320-F600 | 96.0 | 0.4 | 0.4 | 0.15 | ||

F800-F1000 | 95.0 | 0.5 | 0.5 | 0.15 | ||

F1200 | 94.0 | 0.5 | 0.5 | 0.15 | ||

碳化硅砂子及微粉

纯度98%及以上

日标,欧标及国标

Grit | Size Arrange(µ m) | |||

China GB (GB/T 2481.1-1998) | ISO8486.1:1996 & FEPA42GB-1984 | JIS R6001-1998 | ANSI B74.12-1992 | |

F4 | 5600~4750 | 5600~4750 | ||

F5 | 4750~4000 | 4750~4000 | ||

F6 | 4000~3350 | 4000~3350 | ||

F7 | 3350~2800 | 3350~2800 | ||

F8 | 2800~2360 | 2800~2360 | 2800~2360 | |

F10 | 2360~2000 | 2360~2000 | 2360~2000 | |

F12 | 2000~1700 | 2000~1700 | 2000~1700 | |

F14 | 1700~1400 | 1700~1400 | 1700~1400 | |

F16 | 1400~1180 | 1400~1180 | 1400~1180 | |

F20 | 1180~1000 | 1180~1000 | 1180~1000 | |

F22 | 1000~850 | 1000~850 | - | |

F24 | 850~710 | 850~710 | 850~710 | |

F30 | 710~600 | 710~600 | 710~600 | |

F36 | 600~500 | 600~500 | 600~500 | |

F40 | 500~425 | 500~425 | - | |

F46 | 425~355 | 425~355 | 425~355 | |

F54 | 355~300 | 355~300 | 355~300 | |

F60 | 300~250 | 300~250 | 300~250 | |

F70 | 250~212 | 250~212 | 250~212 | |

F80 | 212~180 | 212~180 | 212~180 | |

F90 | 180~150 | 180~150 | 180~150 | |

F100 | 150~125 | 150~125 | 150~125 | |

F120 | 125~106 | 125~106 | 125~106 | |

F150 | 106~75 | 106~75 | 106~75 | |

F180 | 90~63 | 90~63 | 90~63 | |

F220 | 75~53 | 75~53 | 75~53 | |

F240 | - | - | 75~53 | |

China GB 国标 | JIS R6001-1998 日标 | ANSI B74.12-1992 美标 | FEPA 42GB-1984 DIN 69101-1985德国标准 | |||||||||

GB/T2481.2-1998 | GB/T9258.1-2000 | Grit | d50(µ m) | Grit | d50(µ m) | Grit | d50(µ m) | |||||

Grit | d50 (µ m) | Grit | d50 (µ m) | Sedimentation tube menthod | Electric resisance method | Sedimentation tube menthod | Standard Werte der Mlkro-Frelhe | Sedigraph 5000D | ||||

P240 | 58.5±2.0 | 240 | 60.0±4.0 | 57.0±3.0 | ||||||||

P280 | 52.2±2.0 | 280 | 52.0±3.0 | 48.0±3.0 | ||||||||

F230 | 53.0±3.0 | P320 | 46.2±1.5 | 320 | 46.0±2.5 | 40.0±2.5 | 240 | 53.5-50 | F230 | 53.0±3.0 | 50.0±3.0 | |

F240 | 44.5±2.0 | P360 | 40.5±1.5 | 360 | 40.0±2.0 | 35.0±2.0 | F240 | 44.5±2.0 | 42.0±2.0 | |||

P400 | 35.0±1.5 | 400 | 34.0±2.0 | 30.0±2.0 | 280 | 44-40.5 | ||||||

F280 | 36.5±1.5 | P500 | 30.2±1.5 | 500 | 28.0±2.0 | 25.0±2.0 | 320 | 36-32.5 | F280 | 36.5±1.5 | 34.5±1.5 | |

F320 | 29.2±1.5 | P600 | 25.8±1.0 | 600 | 24.0±1.5 | 20.0±1.5 | 360 | 28.8-25.8 | F320 | 29.2±1.5 | 27.7±1.5 | |

F360 | 22.8±1.5 | P800 | 21.8±1.0 | 700 | 21.0±1.3 | 17.0±1.3 | 400 | 23.6-20.6 | F360 | 22.8±1.5 | 21.6±1.5 | |

F400 | 17.3±1.0 | P1000 | 18.3±1.0 | 800 | 18.0±1.0 | 14.0±1.0 | 500 | 19.7-16.7 | F400 | 17.3±1.0 | 16.5±1.0 | |

F500 | 12.8±1.0 | P1200 | 15.3±1.0 | 1000 | 15.5±1.0 | 11.5±1.0 | 600 | 16-13 | F500 | 12.8±1.0 | 12.3±1.0 | |

P1500 | 12.6±1.0 | 1200 | 13.0±1.0 | 9.5±0.8 | ||||||||

F600 | 9.3±1.0 | P2000 | 10.3±0.8 | 1500 | 10.5±1.0 | 8.0±0.6 | 800 | 12.3-9.8 | F600 | 9.3±1.0 | 9.0±1.0 | |

P2500 | 8.4±0.5 | 2000 | 8.5±0.7 | 6.7±0.6 | 1000 | 9.3-6.8 | ||||||

F800 | 6.5±1.0 | 2500 | 7.0±0.7 | 5.5±0.5 | F800 | 6.5±1.0 | 6.3±1.0 | |||||

F1000 | 4.5±0.8 | 3000 | 5.7±0.5 | 4.0±0.5 | 1200 | 6.5-4.5 | F1000 | 4.5±0.8 | 4.5±0.8 | |||

F1200 | 3.0±0.5 | 4000 | 3.0±0.4 | F1200 | 3.0±0.5 | 3.1±0.5 | ||||||

6000 | 2.0±0.4 | |||||||||||

8000 | 1.2±0.3 | |||||||||||

25KG袋子及托盘